Saito Seiki will keep moving forward to become a next-level manufacturer of various special purpose machines and equipment.

-

- Company Name

- Saito Seiki. Co., Ltd.

-

- Founded in

- May 1939

-

- Representative

- Takeshi Saito, President

-

- Address

- (Factory 1,2, and 3): 1-chōme-21-18 Fuchinobe, Chuo Ward, Sagamihara, Kanagawa 252-0206

-

- Capital

- 10,000,000 JPY

-

- Business Description

- - Designing and manufacturing of various special purpose machines and equipment related to solar cells - Designing and manufacturing of various special purpose machines and equipment related to semiconductors - Designing, manufacturing, and contract machining of general-purpose machines and equipment related to optical glass - Designing and manufacturing of various special purpose machines and equipment related to automobiles, aircrafts, and artificial satellites - Prototyping and contract machining using special purpose machines

-

- Main Banks

- Machida Branch of MUFG Bank Fuchinobe Branch of The Bank of Yokohama Machida Branch of Resona Bank Fuchinobe Branch of Kiraboshi Bank

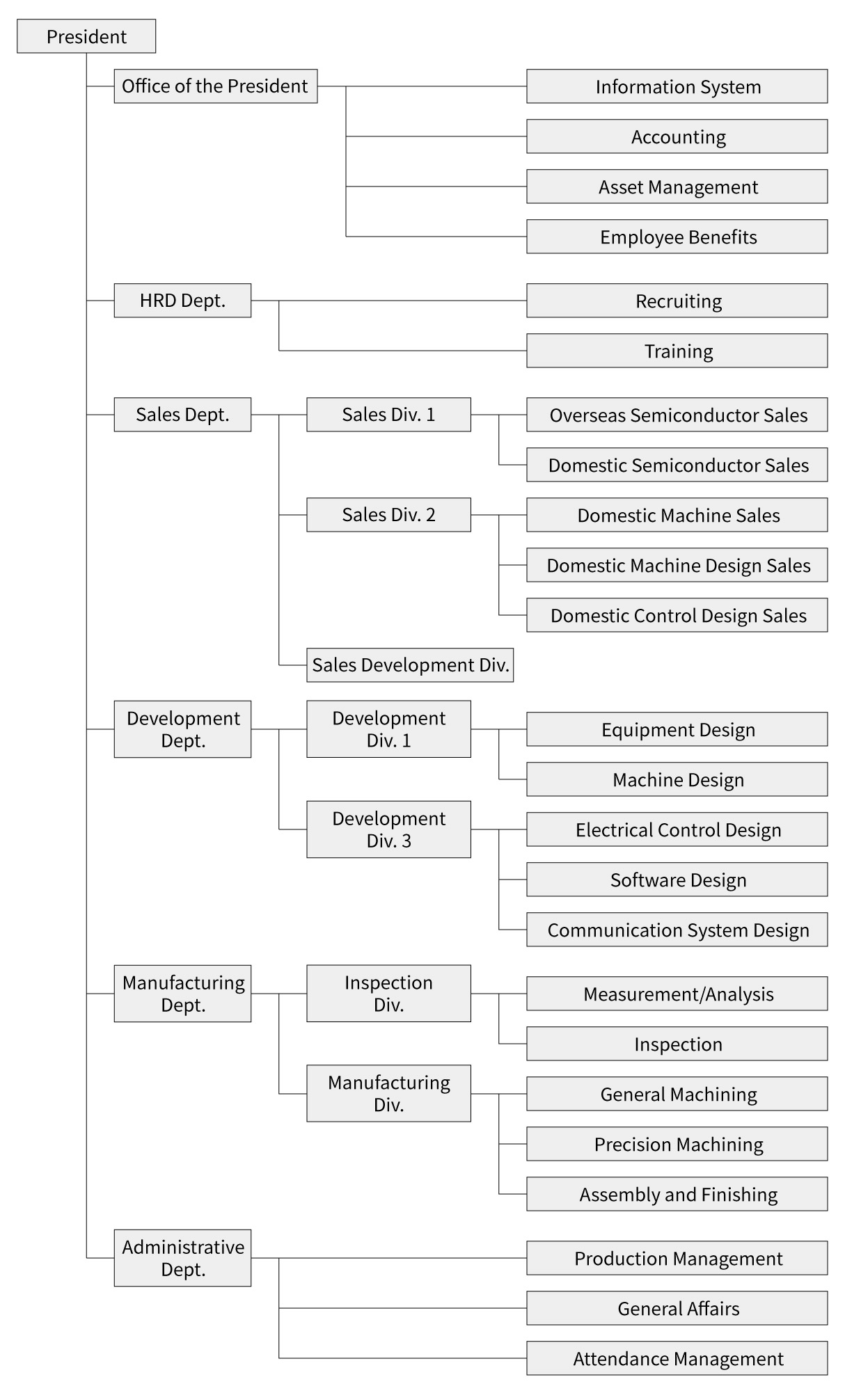

Company Organization Chart

History

-

- May 1939

- Saito Seisakusho was founded in Omori, Tokyo as a precision components manufacturing plant.

As a subcontract factory of the Sagamihara Military Arsenal, the company specializes in the manufacture of diesel and nozzle holders for tanks.

-

- April 1945

- Evacuated to Negishi, Machida City, Tokyo due to the war. The war ended while the company was preparing to start its operation.

-

- February 1946

- Converted to a private-sector business and began automotive and electrical parts machining. Expanded its business to become a designer and manufacturer of various special-purpose machines and jigs.

-

- November 1971

- Moved the head office functions to a new building at the current address.

-

- May 1980

- Started the development and manufacture of silicon ingot processors for semiconductors.

-

- July 1988

- Expanded the second plant at the head office to increase the assembly department.

Introduced jig boring machines (made by Dixi, a Swiss company) and precision machining centers.

Built a CAD environment aiming for more efficient and flexible designs.

-

- 1997

- As one of the commemorative projects of the 60th anniversary of the company's founding, the third machine factory was built.

Started to use the #6 Jig Boring Machine (made by Mitsui Seiki) and Kellenberger 1000U grinding machines.

-

- 2002

- Started to focus on the design and manufacture of new special-purpose machines and jigs based on the most advanced technology, with an eye toward special-purpose machines for systems that integrate with computers.

-

- 2004

- Started glass machining as a new business.

Contracted glass plate machining for large flat panel equipment.

-

- 2008

- As one of the commemorative projects of the 70th anniversary of the company's founding, the fourth factory was built.

-

- 2009

- Started the development and manufacture of silicon ingot processors for solar cells.

-

- 2016

- Obtained KCs (Korea Certification for safety).

-

- 2018

- Released Non-contact Semiconductor Precision Measurement Equipment.

-

- 2020

- Developed our own GEM communication format.